As we’ve seen in the previous posts, specifying and reproducing color in RGB needs to be done very carefully. You need to specify which RGB, and not every monitor or screen is the same. But what about that other reproduction technology: printing? You might think it’s easy, printing. At the office, you just hit the ‘print’ button, and that small machine puts your pretty designs on paper. So, shouldn’t those big, expensive printing presses act the same? Not really.

For a starter, there are multiple, quite different printing technologies. Depending on what kind of substrate you want to print on, the size of a print job, you (or your printing company) will pick one or the other. There are large inkjet and laser printers (or, to be more precise about that last one: electrophotography), these are well equipped for smaller run lengths and for ‘variable data printing’, where every copy is different.

Next to these digital printing technologies, there are several analog or conventional technologies. The most common is offset lithography (or ‘offset’ in short), which is used for general printing applications and often for newspapers and magazines. Then, there is flexography, mainly used for packaging (e.g., flexible substrates) and labels. For very large print runs (millions of copies), both publishing and packaging, there is gravure printing. For textiles, screen printing is the preferred technology, but also for very large formats (which don’t fit on the other analog presses). And then there is tampon or pad printing, which is used to print on pens, and other objects that are not flat.

There still are others, but you probably won’t encounter these.

Every printing technology has its properties, advantages, and disadvantages. Every printing press needs to be operated by a skilled person, who can get all the parameters right. It is more complex than hitting that ‘print’ button. However, automation and inline quality control have made the life of press operators a bit easier over the years.

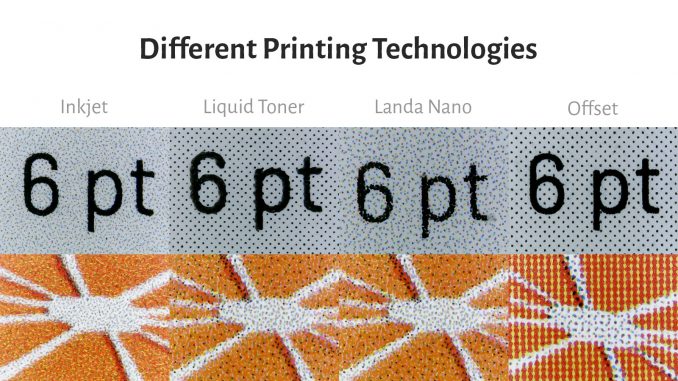

The top images show 4 different technologies: inkjet (Canon Vairoprint i3200), liquid toner (HP Indigo 100000), Landa Nano (which is also inkjet, but with a twist), and offset. These images come from a sample set provided by Print.com (here’s more information about their excellent sample kit). Now, be careful! These images were taken with a microscope, regular ‘print consumers’ will never look at a print job like this! Only people who do quality control might look at print like this. Print consumers will look at a print job from a regular reading or looking distance (depending on the print size and application). And when doing that, all those fine dots will merge into one color… So, don’t complain about those tiny dots, look at the print job from an average viewing distance!

There are a lot more factors that might influence your brand color, check out the Project BBCG tutorial to find out more! And if English is not your native language, check out the available translations!